Product Information

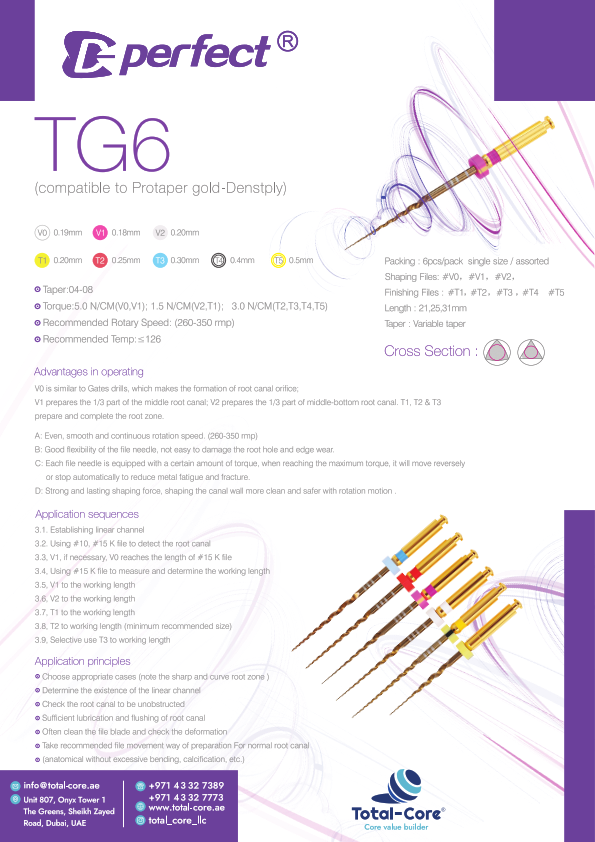

TG6

Perfect Rotary Instruments

Supper Files System: Heat treated rotary file system with gold standard and give amazing flexibility.

TG6 Total Core

(compatible to Protaper gold – Denstply)

Packing: 6pcs/pack

Single size/ assorted

Shaping Files: #V0, #V1 , #V2

Length: 21, 25, 31 mm

Taper: Variable taper

- Taper: 04-08

- Torque: 5.0 N/CM(V2,T1); 0 N/CM (T2,T3,T4,T5)

- Recommended Rotary Speed: (260-350rmp)

- Recommended Temp: ≤ 126

Advantages in operating

V0 is similar to Gates drills, with makes the formation of root canal orifice:

V1 prepares the 1/3 part of the middle root canal; V2 prepares the 1/3 part of middle- bottom root canal. T1 , T2 & T3 prepare and complete the root zone.

A: Even, smooth and continuous rotation speed. (260-350rmp)

B: Good flexibility of the file needle, not easy to damage the root hole and edge wear.

C: Each file needle is equipped with a certain amount of torque, when reaching the maximum torque, it will move reversely or stop automatically to reduce metal fatigue and fracture.

D: Strong and lasting shaping force, shaping the canal wall more clean and safer with rotation motion.

Application sequences

3.1 Establishing linear channel 3.2 Using # 10, # 15 K file to detect the root canal

3.3 V1, if necessary, V0 reaches the length of # 15 K file

3.4 Using # 15 K file to measure and determine the working length

3.5 V1 to the working length

3.6 V2 to the working length

3.7 T1 to the working length

3.8 T2 to working length (minimum recommended size)

3.9 Selective use T3 to working

Application principle

- Choose appropriate cases (note the sharp and curve root zone)

- Determine the existence of the linear channel

- Check the root canal to be unobstructed

- Sufficient lubrication and flushing of root canal

- Often clean the file blade and check the deformation

- Take recommended file movement way of preparation For normal root canal

- (anatomical without excessive bending, calcification, etc.)

Technical Features

| Material | NiTi |